Chemgrout Pumps

ChemGrout started in 1963 as grouting contractors providing cement and chemical grouting field services. Invaluable experience was gained in the field on over 350 projects, both large and small. This field experience enables us to understand your needs and recommend the proper equipment for your application.

ChemGrout equipment was originally designed for its own use. That is why the units are engineered and constructed for rugged field use, portability and low maintenance

Each ChemGrout unit is designed for “balance” of grout delivery. Complete grouting units are always designed to allow the user continuous, non-stop grouting capability at published pumping rates for the unit. That is, the mixing tank is large and fast enough, and the storage hopper has a large enough capacity to keep the pump “fed” without interruption.

Today, ChemGrout manufactures a wide range of standard and custom-built grouting equipment to handle a diverse range of materials and capacities from 1 to 75 GPM and pressures from 50 to 2000 PSI. High-pressure pumps handle pressures to 2000 PSI and flows to 50 GPM. Systems can be skid or trailer mounted with power options that include air, gasoline, diesel, electric and hydraulic.

For more information and a complete description of the pumps we offer by CHEMGROUT, please click on the links below.

CG-05M Hand Grout Pump

CG-05 Mini Hand Grout Pump

CG-550P Mini Hand Grout Pump Mixer

CG-550/030 Rugged Series

CG-550/030 Rugged Trailer

CG-550/C4 Workhorse Series

CG-550/C4 Workhorse Trailer

CG-570/3C6 Thick-Mix Series

CG-575/3C6 Thick-Mix Trailer

CG-550/2L4 Thin-Mix Series

CG-555/2L4 Thin-Mix Trailer

CG-500/031/GT High Capacity Geotech Series

CG-500/031/GT High Capacity Geotech Trailer

CG-502/C4 Sprayer/Finisher

CG-502/031 Multi-Purpose Grouter

CG-500HP High-Pressure Series

CG-580 High-Pressure Series

CG-580 High-Capacity Series

High-Pressure Colloidal Series

CG-600HP High-Pressure Colloidal Series

CG-460HP High-Pressure Colloidal Series

CG-680 High-Pressure & Colloidal Mixer Series

CG-542 Mining Grouter

CG-600 Colloidal Series

CG-680 High-Capacity Colloidal Mixer Series

CG-620 Colloidal Mixer Series

Mini-Series

CG-050M Hand Grout Pump

The ChemGrout model CG-050M is a portable, skid mounted, hand operated grout pump. The lightweight aluminum design makes this grout pump perfect for smaller jobs. This unit features a 5 gallon holding hopper and a piston pump. The holding hopper is connected directly to the suction of the pump for a continuous pumping operation. The grout pump is a 2″ positive displacement manually powered pulsating piston pump. The system disassembles without any tools for a fast and efficient cleaning. The pump comes complete and ready to use with a free 12.5 foot grout hose and a set of spare piston cups.

Weight Dry:......................................... 52 lbs

Length:................................................ 44"

Width:.................................................. 11"

Height:................................................ 31"

Mount:................................................ Skid Mounted

Power:................................................ Manual

Pump:................................................. 2" Piston

Hopper Capacity:............................... 5 gal.

Max Output:....................................... 2-3 GPM

Max Pressure:................................... 200 psi

CG-050 Mini Hand Grout Pump

The ChemGrout model CG-050 is a portable, skid mounted, air or hydraulic powered grout pump. The lightweight aluminum construction makes this model portable for hard to reach jobs. The holding hopper is connected directly to the suction of the grout pump to provide a continuous pumping operation. The grout pump is a 2″ positive displacement, pulsating piston. This grout pump is available with either an air or hydraulic cylinder to power the pump. All components are easily accessible for operating, cleaning and maintenance. The pump comes complete and ready to use with a 12.5 foot grout hose and a set of spare piston cups.

Weight Dry:......................................... 55 lbs

Length:................................................ 44"

Width:.................................................. 11"

Height:................................................ 24"

Mount:................................................ Skid Mounted

Power:................................................ Air

Pump:................................................. 2" Piston

Hopper Capacity:............................... 5 gal.

Max Output:....................................... 5 GPM

Max Pressure:................................... 225 psi

CG-550P Mini Hand Grout Pump & Mixer

The ChemGrout model CG-550P is a skid mounted, air powered grout machine. This system is designed to provide a continuous operation of mixing and pumping. This unit features a 34 gallon (129 liter) mixing tank and the field proven CG-050 grout pump. The mixer is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide a rapid mixing cycle. The tank outlet valves are large slide gates that allow the thickest materials to fall easily into the pump hopper. The holding hopper is connected directly to the suction of the grout pump to provide a continuous pumping operation. The grout pump is a 2″ positive displacement, pulsating piston. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. The pumping components disassemble without any tools for a fast and efficient cleaning. All components are easily accessible for operating, cleaning and maintenance. The pump comes complete and ready to use with a 12.5 foot grout hose and a set of spare piston cups.

Weight Dry:......................................... 300 lbs

Length:................................................ 48"

Width:.................................................. 27"

Height:................................................ 57"

Mount:................................................ Skid Mounted

Power:................................................ Air

Pump:................................................. 2" Piston

Mixing Tank:....................................... 34 gal.

Hopper Capacity:............................... 5 gal.

Max Output:....................................... 5 GPM

Max Pressure:................................... 225 psi

Rugged Series

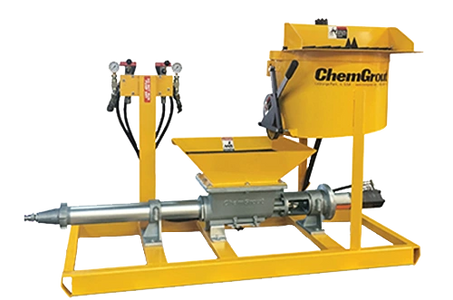

CG-550/030 Rugged Series

The ChemGrout CG-550 Rugged series includes both skid and trailer mounted grout plants. These units feature a 45-gallon (170 liters) mixing tank, a large 30-gallon (113 liters) holding hopper and the popular single-acting 3″ piston grout pump. Each mixing tank is equipped with baffles, bag breakers and a variable speed high-efficiency paddle mixer that provides rapid grout mixing. The tank outlet is a large slidegate that allows viscous grouting materials to flow quickly into the removable holding hopper. The large holding hopper is sized to provide continuous pumping, the mixer is charged while the hopper feeds the pump, an optional 18-gallon (68 liter) hopper is available for thick pasty materials like repair mortars. The grout pump is a 3″ positive displacement, pulsating piston pump that disassembles with only a hammer for fast and thorough cleaning. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. The trailer mounted unit is road and job site ready equipped with leaf springs, lights and a working platform.

Weight Dry:......................................... 490 lbs

Length:................................................ 64"

Width:.................................................. 31"

Height:................................................ 56"

Mount:................................................ Skid Mounted

Power:................................................ Air / Hydraulic

Pump:................................................. 3" Piston

Mixing Tank:....................................... 45 gal.

Hopper Capacity:............................... 18 or 30 gal.

Max Output:....................................... 16 GPM / 12 GPM

Max Pressure:................................... 400 psi / 550 psi

CG-550/030 Rugged Trailer

The ChemGrout CG-550 Rugged series includes both skid and trailer mounted grout plants. These units feature a 45-gallon (170 liters) mixing tank, a large 30-gallon (113 liters) holding hopper and the popular single-acting 3″ piston grout pump. Each mixing tank is equipped with baffles, bag breakers and a variable speed high-efficiency paddle mixer that provides rapid grout mixing. The tank outlet is a large slidegate that allows viscous grouting materials to flow quickly into the removable holding hopper. The large holding hopper is sized to provide continuous pumping, the mixer is charged while the hopper feeds the pump, an optional 18-gallon (68 liter) hopper is available for thick pasty materials like repair mortars. The grout pump is a 3″ positive displacement, pulsating piston pump that disassembles with only a hammer for fast and thorough cleaning. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. The trailer mounted unit is road and job site ready equipped with leaf springs, lights and a working platform.

Weight Dry:......................................... 1495 lbs

Length:................................................ 110"

Width:.................................................. 68"

Height:................................................ 70"

Mount:................................................ Trailer Mounted

Power:................................................ Air / Hydraulic

Pump:................................................. 3" Piston

Mixing Tank:....................................... 45 gal.

Hopper Capacity:............................... 18 or 30 gal.

Max Output:....................................... 16 GPM / 12 GPM

Max Pressure:................................... 400 psi / 550 psi

Workhorse Series

CG-550/C4 Workhorse Series

The ChemGrout CG-550 Workhorse series includes both skid and trailer mounted grouting equipment. This workhorse unit is designed to mix and pump neat cement, bentonite, cement/bentonite, cement/sand, non-shrink, self leveling and most packaged grout mixes. These units feature a 45 gallon (170 liters) mixing tank, a 12 gallon (45 liters) holding hopper and a 8 GPM (30 LPM) progressive cavity grout pump. The balanced design of this grout plant allows continuous mixing and pumping, while the hopper is feeding the pump another batch can be mixed. The mix tank is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valves are large slide gates that allow the thickest materials to fall easily into the pump hopper. The grout pump is a variable speed, positive displacement, progressive cavity, rotor-stator pump. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning, and maintenance. The trailer mounted unit is road and job site ready equipped with leaf springs, lights and a working platform.

Weight Dry:......................................... 700 lbs / 600 Lbs

Length:................................................ 72"

Width:.................................................. 63" / 55"

Height:................................................ 56"

Mount:................................................ Skid Mounted

Power:................................................ Air Powered / Hydraulic

Pump:................................................. Progressive Cavity - 2 Stage, Size 4, Open Throat / 3 Stage, Size 4, Open Throat

Mixing Tank:....................................... 45 gal.

Hopper Capacity:............................... 12 gal.

Max Output:....................................... 8 GPM

Max Pressure:................................... 174 psi / 261 psi

CG-555/C4 Workhorse Trailer

The ChemGrout CG-550 Workhorse series includes both skid and trailer mounted grouting equipment. This workhorse unit is designed to mix and pump neat cement, bentonite, cement/bentonite, cement/sand, non-shrink, self leveling and most packaged grout mixes. These units feature a 45 gallon (170 liters) mixing tank, a 12 gallon (45 liters) holding hopper and a 8 GPM (30 LPM) progressive cavity grout pump. The balanced design of this grout plant allows continuous mixing and pumping, while the hopper is feeding the pump another batch can be mixed. The mix tank is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valves are large slide gates that allow the thickest materials to fall easily into the pump hopper. The grout pump is a variable speed, positive displacement, progressive cavity, rotor-stator pump. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning, and maintenance. The trailer mounted unit is road and job site ready equipped with leaf springs, lights and a working platform.

Weight Dry:......................................... 1550 lbs / 1700 lbs

Length:................................................ 110"

Width:.................................................. 68"

Height:................................................ 73"

Mount:................................................ Trailer Mounted

Power:................................................ Gas/Hydraulic / Diesel/Hydraulic

Pump:................................................. Progressive Cavity - 2 Stage, Size 4, Open Throat / 3 Stage, Size 4, Open Throat

Mixing Tank:....................................... 45 gal.

Hopper Capacity:............................... 12 gal.

Max Output:....................................... 8 GPM

Max Pressure:................................... 174 psi / 261 psi

Thick-Mix Series

CG-570/3C6 Thick-Mix Series

The ChemGrout CG-570 Thick Mix Series includes both skid and trailer mounted grout plants. This machine will continuously mix and pump the widest range of grouting materials from thin to thick consistencies. Materials that are used with this unit include Repair Mortars, Gel Mortars, Stucco, Fireproofing Plastering, EIFS, cement/masonry sand, cement/fly ash, flowable and non-flowable grouts and Bentonite waterproofing grouts. The optional air compressor allows the operator to continuously mix, pump and spray. The 45 gal mixing tank is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valves are large slide gates that allow the thickest materials to fall easily into the pump hopper. The holding hopper has an auger in it to keep the material thoroughly mixed while constantly supplying the grout pump with material for the continuous pumping operation. The grout pump is a Size 6, 3 stage, variable speed, positive displacement, progressive cavity, rotor-stator pump that delivers up to 8 GPM, 580 PSI. These units can be powered by compressed air or their own hydraulic power systems that feature 15 HP Electric motor, 20 HP Gasoline engine or 20 HP Diesel engine, both equipped with electric start. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning, and maintenance. The highway ready trailer comes complete with leaf springs, lights, a working platform and an adjustable trailer hitch for either ball or pintle

Weight Dry:......................................... 750 lbs

Length:................................................ 74"

Width:.................................................. 31"

Height:................................................ 53" / 58"

Mount:................................................ Skid Mounted

Power:................................................ Air / Hydraulic

Pump:................................................. Progressive Cavity - 3 Stage, Size 6, Open Throat

Mixing Tank:....................................... 45 gal.

Hopper Capacity:............................... 15 gal.

Max Output:....................................... 2-8 GPM

Max Pressure:.................................... 580 psi

CG-575/3C6 Thick-Mix Trailer

The ChemGrout CG-570 Thick Mix Series includes both skid and trailer mounted grout plants. This machine will continuously mix and pump the widest range of grouting materials from thin to thick consistencies. Materials that are used with this unit include Repair Mortars, Gel Mortars, Stucco, Fireproofing Plastering, EIFS, cement/masonry sand, cement/fly ash, flowable and non-flowable grouts and Bentonite waterproofing grouts. The optional air compressor allows the operator to continuously mix, pump and spray. The 45 gal mixing tank is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valves are large slide gates that allow the thickest materials to fall easily into the pump hopper. The holding hopper has an auger in it to keep the material thoroughly mixed while constantly supplying the grout pump with material for the continuous pumping operation. The grout pump is a Size 6, 3 stage, variable speed, positive displacement, progressive cavity, rotor-stator pump that delivers up to 8 GPM, 580 PSI. These units can be powered by compressed air or their own hydraulic power systems that feature 15 HP Electric motor, 20 HP Gasoline engine or 20 HP Diesel engine, both equipped with electric start. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning, and maintenance. The highway ready trailer comes complete with leaf springs, lights, a working platform and an adjustable trailer hitch for either ball or pintle.

Weight Dry:......................................... 1400 lbs / 1500 lbs

Length:................................................ 110"

Width:.................................................. 68"

Height:................................................. 70"

Mount:................................................ Trailer Mounted

Power:................................................ Gas / Hydraulic

Pump:................................................. Progressive Cavity - 3 Stage, Size 6, Open Throat

Mixing Tank:....................................... 45 gal.

Hopper Capacity:............................... 15 gal.

Max Output:....................................... 2-8 GPM

Max Pressure:.................................... 580psi

Thin-Mix Series

CG-550/2L4 Thin-Mix Series

The ChemGrout CG-550 Thin Mix series includes both skid and trailer mounted grouting equipment. The Thin Mix unit is designed to mix and pump neat cements, bentonites, cement/bentonites, and lightly sanded grout mixes. These units feature a 45 gallon (170 liters) mixing tank, a 15 gallon (57 liters) holding hopper and a 8 GPM (30 LPM) progressive cavity grout pump. The balanced design of this grout plant allows continuous mixing and pumping, while the hopper is feeding the pump another batch can be mixed. The mix tank is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valve is a large slide gate that allows the materials to fall easily into the pump hopper. The grout pump is a variable speed, positive displacement, progressive cavity, rotor-stator pump. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning, and maintenance. The trailer mounted unit is road and job site ready equipped with leaf springs, lights and a working platform.

Weight Dry:......................................... 550 lbs

Length:................................................ 73"

Width:.................................................. 31"

Hopper Height:................................... 51"

Mount:................................................ Skid Mounted

Power:................................................ Air / Hydraulic

Pump:................................................. Progressive Cavity - 2 Stage, Size 4, Flanged Inlet / 3 Stage, Size 4, Flanged Inlet

Mixing Tank:....................................... 45 gal.

Hopper Capacity:............................... 15 gal.

Max Output:....................................... 8 GPM

Max Pressure:................................... 174psi / 261 psi

CG-555/2L4 Thin-Mix Trailer

The ChemGrout CG-550 Thin Mix series includes both skid and trailer mounted grouting equipment. The Thin Mix unit is designed to mix and pump neat cements, bentonites, cement/bentonites, and lightly sanded grout mixes. These units feature a 45 gallon (170 liters) mixing tank, a 15 gallon (57 liters) holding hopper and a 8 GPM (30 LPM) progressive cavity grout pump. The balanced design of this grout plant allows continuous mixing and pumping, while the hopper is feeding the pump another batch can be mixed. The mix tank is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valve is a large slide gate that allows the materials to fall easily into the pump hopper. The grout pump is a variable speed, positive displacement, progressive cavity, rotor-stator pump. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning, and maintenance. The trailer mounted unit is road and job site ready equipped with leaf springs, lights and a working platform.

Weight Dry:......................................... 1400 lbs

Length:................................................ 110"

Width:.................................................. 68"

Hopper Height:................................... 70"

Mount:................................................ Trailer Mounted

Power:................................................ Diesel / Hydraulic

Mixing Tank:....................................... 45 gal.

Hopper Capacity:............................... 15 gal.

Max Output:....................................... 8 GPM

Max Pressure:................................... 174 - 261 psi

Geotech Series

CG-500/031/GT High Capacity Geotech Series

The ChemGrout CG-550 Geotech Series includes both skid and trailer mounted grout plants. These units feature a 70-gallon (265 liters) mixing tank, a large 45-gallon (170 liters) holding hopper and the rugged single-acting 3″ piston grout pump. The mixing tank is equipped with baffles, bag breaker and a variable speed high-efficiency paddle mixer that provides rapid grout mixing. The tank outlet is a large slide gate that allows viscous grouting materials to flow quickly into the removable holding hopper. The large holding hopper is sized to provide continuous pumping, the mixer is charged while the hopper feeds the pump. The grout pump is a 3″ positive displacement, single acting piston pump that disassembles with only a hammer for fast and thorough cleaning. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. The trailer mounted unit is road and job site ready equipped with leaf springs, lights and a working platform.

Shown with optional water batcher.

Weight Dry:......................................... 690 lbs

Length:................................................ 66"

Width:.................................................. 34"

Hopper Height:................................... 58"

Mount:................................................ Skid Mounted

Power:................................................ Air / Hydraulic

Pump:................................................. Single Acting Piston

Mixing Tank:....................................... 70 gal.

Hopper Capacity:............................... 45 gal.

Max Output:....................................... 20 GPM / 16 GPM

Max Pressure:................................... 400 psi / 550 psi

CG-500/031/GT High Capacity Geotech Trailer

The ChemGrout CG-550 Geotech Series includes both skid and trailer mounted grout plants. These units feature a 70-gallon (265 liters) mixing tank, a large 45-gallon (170 liters) holding hopper and the rugged single-acting 3″ piston grout pump. The mixing tank is equipped with baffles, bag breaker and a variable speed high-efficiency paddle mixer that provides rapid grout mixing. The tank outlet is a large slide gate that allows viscous grouting materials to flow quickly into the removable holding hopper. The large holding hopper is sized to provide continuous pumping, the mixer is charged while the hopper feeds the pump. The grout pump is a 3″ positive displacement, single acting piston pump that disassembles with only a hammer for fast and thorough cleaning. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. The trailer mounted unit is road and job site ready equipped with leaf springs, lights and a working platform.

Shown with optional water batcher.

Weight Dry:......................................... 1700 lbs

Length:................................................ 110"

Width:.................................................. 68"

Hopper Height:................................... 76"

Mount:................................................ Trailer Mounted

Pump:................................................. Single Acting Piston

Power:................................................ Air / Hydraulic

Mixing Tank:....................................... 70 gal.

Hopper Capacity:............................... 45 gal.

Max Output:....................................... 20 GPM / 16 GPM

Max Pressure:................................... 400 psi (28 bar) / 550 psi (38 bar)

Sprayer / Finisher Series

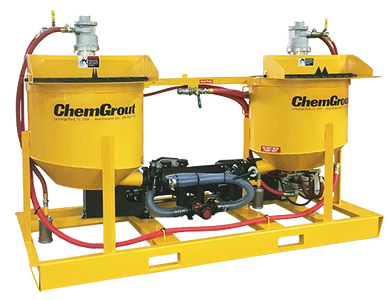

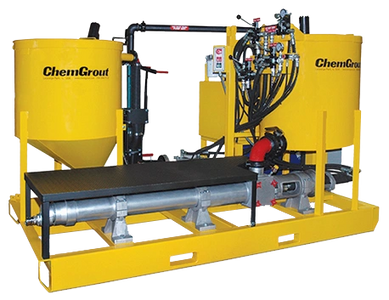

CG-502/2C4 Sprayer/Finisher

The ChemGrout Sprayer/Finisher Series is specially designed to offer the flexibility for both pump and spray applications. Its twin 45-gallon mixing tanks, pump, and large holding hopper are all mounted on a single skid for quick, easy set-up and immediate operation. The low profile mix tanks enable greater ease when dispensing bags for dry material, reducing operator fatigue and increasing productivity. The tanks feature high-efficiency paddles that provide a rapid mixing cycle and ensure a smooth, consistent material mix. Each mix tank alternates feeding a centrally located holding hopper allowing for a continuous, non-stop process. The 502/2C4 features an open throat, size 4 progressive cavity pump and non-pulsating positive displacement rot-stator as standard. The ChemGrout 2C4 pump allows for a steady and continuous flow of material, ideal for self-leveling underlayments, fine non-shrink grouts and most other spray and injection applications. A hinged cleanout port has been added to the suction housing for quick access and clean-up. Complete with optional wheels, and only 31 inches wide, the CG502 offers the mobility required to move quickly and easily through standard size doorways. The rugged steel frame stands up to the toughest jobsite conditions. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance.

Weight Dry:......................................... 800 lbs / 820 lbs / 1150 lbs / 1300 lbs / 1400 lbs

Length:................................................ 82"

Width:.................................................. 31"

Hopper Height:................................... 57"

Mount:................................................ Skid Mounted

Power:................................................ Air/Hydraulic / Electric/Hydraulic / Gas/Hydraulic / Diesel/Hydraulic

Pump:................................................. Progressive Cavity - 2 Stage, Size 4, Open Throat / 3 Stage, Size 4, Open Throat

Mixing Tank:....................................... 2 - 45 gal Tanks

Hopper Capacity:............................... 12 gal.

Max Output:....................................... 10 GPM

Max Pressure:................................... 174 psi / 261 psi

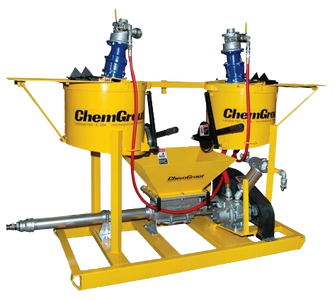

CG-502/031 Multi-Purpose Grouter

The ChemGrout model CG502/031 is a skid mounted grout plant. This unit is designed for maximum efficiency by allowing simultaneous operation of the mixing and pumping. The ChemGrout model CG-502 features two 45 gallon mixing tanks, a 30 gallon holding hopper, and the popular single-acting 3″ piston grout pump. The unique double mix tank design permits continuous pumping as each mix tank alternates feeding the pump. Each mixing tank is equipped with baffles, bag breakers and a variable speed high-efficiency paddle mixer that provides rapid grout mixing. The tank outlet is a large slide gate that allows viscous grouting materials to flow quickly into the removable holding hopper. The large holding hopper is sized to provide continuous pumping. The grout pump is a 3″ positive displacement, pulsating piston pump that disassembles with only a hammer for fast and thorough cleaning. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance.

Weight Dry:......................................... 730 lbs / 930 lbs

Length:................................................ 82"

Width:.................................................. 31"

Hopper Height:................................... 55"

Mount:................................................ Skid Mounted

Power:................................................ Air / Hydraulic

Pump:................................................. 031" Piston

Mixing Tank:....................................... 2 - 45 gal Tanks

Hopper Capacity:............................... 30 gal.

Max Output:....................................... 20 / 16 GPM

Max Pressure:................................... 400 psi / 550 psi

High-Pressure Series

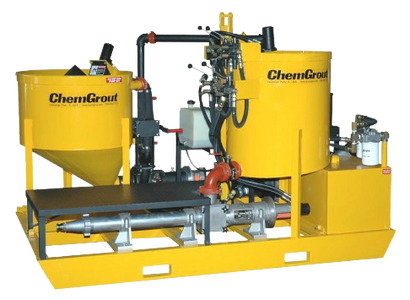

CG-500HP High-Pressure Series

The ChemGrout CG-500HP series are skid mounted, high-pressure grout plants. These units feature two 70-gallon (265 liters) mixing tanks, a 21-gallon (80 liters) holding hopper and a high-pressure plunger grout pump. The unique double mix tank design permits continuous pumping as each mix tank alternates feeding the pump. Each mixer is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlets are large slide gates that allow viscous grouting materials to flow quickly into the removable holding hopper. The holding hopper is connected directly to a positive displacement, double acting 3X8 plunger pump that delivers up to 24 GPM, 1,000 PSI. The pump is also available with 2X8 plunger kits that offer a higher discharge pressure of 2,000 PSI with a slightly lower flow rate of up to 16 GPM. The plunger pump is designed for simple conversion between the pressure outputs by purchasing plunger group conversion kits. The pump has patented fasteners that dramatically reduce disassembly time for cleaning and maintenance. Operator controls are centrally located for efficient production.

Shown with optional water batcher.

Weight Dry:......................................... 1300 lbs / 1100 lbs

Length:................................................ 88'

Width:.................................................. 34"

Hopper Height:................................... 58"

Mount:................................................ Skid Mounted

Power:................................................ Air / Hydraulic

Pump:................................................. 2" x 8" / 3" x 8"

Mixing Tank:....................................... 2 - 70 gal Tanks

Hopper Capacity:............................... 12 gal.

Max Output:....................................... 16 Air/12 Hydraulic GPM / 24 Air/20 Hydraulic GPM

Max Pressure:................................... 2000 psi / 1000 psi

CG-580HP High-Pressure Series

The ChemGrout CG-580/3.5X8 series is a high production volume, high pressure skid mounted grout plant. This versatile unit is designed to mix and pump neat cement, bentonites, lightly sanded grouts and most commercial pre-blended non-shrink grout mixes. This unit features two 128-gallon (480 liters) mixing tanks, a 50-gallon (189 liters) holding hopper and the double acting high pressure plunger grout pump. The unique double mix tank design permits continuous pumping as each mix tank alternates feeding the pump. Each mixer is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valves are large slide gates that allow the thickest materials to fall easily into the pump hopper. The holding hopper supplies the grout pump with material for the continuous pumping operation. The grout pump is a 3.5X8 double acting plunger pump. The plunger pump is also designed for simple conversion between several pressure outputs by purchasing plunger group conversion kits. The pump has patented fasteners that dramatically reduce disassembly time for cleaning and maintenance. The rugged steel frame includes the workers platform and stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning, and maintenance.

Weight Dry:......................................... lbs

Length:................................................ "

Width:.................................................. "

Hopper Height:................................... "

Mount:................................................ Skid Mounted

Power:................................................

Pump:................................................. 3.5" x 8"

Mixing Tank:....................................... 2 - 128 gal Tanks

Hopper Capacity:............................... 50 gal.

Max Output:....................................... 32 GPM

Max Pressure:................................... 1200 psi

High-Capacity Series

CG-580/2C8 High-Capacity Series

The ChemGrout CG-580/C8 series are high production volume skid mounted grout plants. This versatile unit is designed to mix and pump neat cement, sanded grouts and most commercial pre-blended grout mixes. These units feature two 128-gallon (480 liters) mixing tanks, a 70-gallon (265 liters) holding hopper and an open throat progressive cavity grout pump. The unique double mix tank design permits continuous pumping as each mix tank alternates feeding the pump. Each mixer is equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valves are large slide gates that allow the thickest materials to fall easily into the pump hopper. The holding hopper has an auger in it to keep the material thoroughly mixed while constantly supplying the grout pump with material for the continuous pumping operation. The grout pump is an open throat size 8, 2 stage variable speed, positive displacement, progressive cavity, rotor-stator pump. The rugged steel frame includes the worker platform and stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning, and maintenance.

Weight Dry:......................................... 1600 lbs / 1800 lbs

Length:................................................ 96"

Width:.................................................. 37"

Hopper Height:................................... 72"

Mount:................................................ Skid Mounted

Power:................................................ Hydraulic / Electric

Pump:................................................. ChemGrout-2C8

Mixing Tank:....................................... 2 - 128 gal Tanks

Hopper Capacity:............................... 70 gal. Progressive Cavity

Max Output:....................................... 2 Speed, 22 & 44 GPM

Max Pressure:................................... 83 -174 psi (12 bar)

High-Pressure Colloidal Series

CG-600HP High-Pressure Colloidal Series

The ChemGrout CG-600 High Pressure series are skid mounted, colloidal grout plants. This unit is available with a 13 cubic foot high shear colloidal mixer, an agitated storage tank and a high pressure plunger grout pump. The colloidal mixer is equipped with a high shear centrifugal diffuser-type pump that disperses the cementitous material down to its finest particle size to achieve complete particle wetness. The mixing tank is equipped with a bridge breaker to break apart the material before entering the colloidal mixer. The agitated storage tank is available in 13 CF or 17 CF and equipped with a variable speed high-efficiency paddle mixer that maintains a thoroughly mixed grout while waiting to be pumped. The grout pump is connected directly to the agitated storage tank to provide a continuous pumping operation. The grout pump is a double acting, positive displacement plunger style that is available in three different sizes, 3X8 and 2X8, offering discharge pressures of 1,000 psi and 2,000 psi respectively. The double-acting plunger pump is designed so that conversion between the pressure outputs is easy and cost effective. Operator controls are centrally located for efficient production. The pump has patented fasteners that dramatically reduce disassembly time for cleaning and maintenance.

Shown with optional water batcher.

Weight Dry:......................................... 2100 lbs / 1800 lbs

Length:................................................ 97"

Width:.................................................. 60"

Hopper Height:................................... 68"

Mount:................................................ Skid Mounted

Power:................................................ Air / Hydraulic

Pump:.................................................

Grout Pump:...................................... 2" x 8" / 3" x 8"

Max Output:....................................... 14 GPM / 20 GPM Variable Speed,

Max Pressure:................................... 2000 psi / 1000 psi

CG-460HP High-Pressure Colloidal Series

The versatile ChemGrout model CG460/2X8 is a skid mounted, high-pressure grout plant that is designed to mix and pump neat cements at high-pressures. The CG460 features two high shear colloidal 70-gallon (265 liters) mixing tanks, and a double acting, high-pressure plunger type grout pump. Dual 70 gallon colloidal mix tanks allow for independent mixing of flushing and structural grouts. Each mixer is equipped with variable speed, high-efficiency, high shear disks, rotating at speeds up to 3,000 rpm that provides rapid and thorough mixing. The tank outlet valves are a large 4” butterfly type that assures full material flow into pump suction. The grout pump is a double acting, positive displacement plunger style that will deliver 15 GPM (57 l/m), 2000 PSI (138 BAR).

Weight Dry:......................................... 1400 lbs / 1320 Lbs

Length:................................................ 96" / 108

Width:.................................................. 40"

Hopper Height:................................... 56"

Mount:................................................ Skid Mounted

Power:................................................ Air / Hydraulic

Pump:.................................................

Grout Pump:...................................... 2" x 8"

Max Output:....................................... 15 GPM

Max Pressure:................................... 2000 psi

CG-680 High-Pressure & Colloidal Mixer Series

The ChemGrout CG-680 High Pressure series is a high pressure, high capacity, skid mounted colloidal grout plant. The HP colloidal series easily mixes and pumps slurries of cement, flyash, bentonite and lime flour. Each grouting machine in this series is designed to provide a continuous mixing and pumping operation. These units feature a 17 cubic foot homogenizing colloidal mixer, a 17 cubic foot agitated storage tank and a 32 GPM grout pump. The colloidal mixer is equipped with a 2X3X12 high shear centrifugal diffuser-type pump that disperses the cementitous material down to its finest particle size to achieve complete particle wetness. The mixing tank is also equipped with a bridge breaker to break apart the material before entering the colloidal mixer. The agitated storage tank is equipped with a variable speed high-efficiency paddle mixer that maintains a thoroughly mixed grout while waiting to be pumped. The grout pump is connected directly to the agitated storage tank to provide a continuous pumping operation. The grout pump is a positive displacement, high capacity, double acting plunger pump. The rugged steel frame stands up to the toughest conditions on the construction site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance.

Weight Dry:......................................... 3200 lbs / 3800 lbs

Length:................................................ 109" / 121"

Width:.................................................. 60"

Hopper Height:................................... 70" / 79"

Mount:................................................ Skid Mounted

Power:................................................ Electric / Hydraulic

Pump:.................................................

Grout Pump:...................................... 3.5" x 8"

Max Output:....................................... 32 GPM

Max Pressure:................................... 1500 psi

Cable & Rock Bolt Series

CG-542 Mining Grouter

The ChemGrout model CG-542 is a skid mounted air powered grout plant. The unit is specially designed with a low profile for grouting rock bolts and cable stays in tight quarters such as tunnels and mines. This system is designed to provide a mixing and pumping continuous operation. This unit features two 22-gallon mixing tanks, a 10-gallon holding hopper and a progressing cavity grout pump. The mixing tanks are equipped with baffles, bag breakers and variable speed high-efficiency paddles that provide rapid mixing. The tank outlet valves are large slide gates that allow the thickest materials to fall easily into the pump hopper. The holding hopper is equipped with an auger to keep the material thoroughly mixed while waiting to be pumped and in connected directly to the suction of the grout to provide a continuous pumping operation. The grout pump is available in either a 6 stage, size 3, positive displacement, progressing cavity, rotor-stator type that will deliver 3.5 GPM, 522 PSI, or a 3 stage, size 4, positive displacement, progressing cavity, rotor-stator type that will deliver 5 GPM, 261 PSI. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance.

Weight Dry:......................................... 800 lbs / 855 lbs

Length:................................................ 64"

Width:.................................................. 31"

Hopper Height:................................... 52"

Mount:................................................ Skid Mounted

Pump:................................................. Progressive Cavity - 6 Stage, Size 3, Open Throat / 3 Stage Size 4, Open Throat

Power:................................................ Air / Hydraulic

Start:..................................................

Mixing Tank:....................................... 2 - 22 gal Tanks

Hopper Capacity:............................... 10 gal.

Max Output:.......................................3.5 GPM / 5 GPM

Max Pressure:................................... 522 psi / 261 psi

Colloidal Series

CG-600 Colloidal Series

The ChemGrout CG-600 colloidal series are heavy duty, high volume colloidal mixing grout plants for applications that require colloidal mixing like dams, tunnels, post-tensioning, underground mining and many heavy construction jobs. The ChemGrout colloidal series easily mixes and pumps slurries of neat cement, fly ash, bentonite, microfine cements and lime flour. The CG600 colloidal grout plants are available with an 8 cubic foot (220 Liters) or 13 cubic foot (368 L) colloidal mixer, both are designed to provide a continuous mixing and pumping operation. These units feature a ChemGrout 2X3X6 high shear colloidal mix pump, a 13 cubic foot agitated storage tank (17 CF optional) and a 20 GPM progressing cavity grout pump. The colloidal mixer is equipped with a centrifugal diffuser-type pump rotating at speeds up to 2000 RPM that disperses the cementitous material down to its finest particle size to achieve complete particle wetness. The mixing tank is also equipped with a bridge breaker to break apart the material before entering the colloidal mix pump. The agitated storage tank is equipped with a variable speed high-efficiency paddle mixer that maintains a thoroughly mixed grout while waiting to be pumped. The grout pump is connected directly to the agitated storage tank to provide a continuous pumping operation. The grout pump is a size 6, 3 stage progressing cavity, positive displacement, rotor-stator pump. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance.

Weight Dry:......................................... 1550 lbs / 2600 lbs / 2650 lbs

Length:................................................ 90" /86"

Width:.................................................. 60"

Hopper Height:................................... 74" / 65" / 72"

Mount:................................................ Skid Mounted

Power:................................................

Pump:.................................................

Mixing Tank Capacity:........................ 60 - 97 gal

Agitated Storage Tank:....................... 97 gal

Max Output:....................................... 20GPM

Max Pressure:................................... 261psi

CG-680 High-Capacity Colloidal Mixer Series

The ChemGrout CG-680 series includes both skid and trailer mounted equipment. The colloidal series easily mixes and pumps slurries of cement, fly ash, bentonite and lime flour. Each grouting machine in this series is designed to provide a continuous mixing and pumping operation. These units feature a 17 cubic foot high shear colloidal mixer, a 17 cubic foot agitated storage tank and a 45 GPM grout pump. The colloidal mixer is equipped with a high speed centrifugal diffuser-type pump that disperses the cementitous material down to its finest particle size to achieve complete particle wetness. The mixing tank is also equipped with a bridge breaker to break apart the material before entering the colloidal mixer. The agitated storage tank is equipped with a variable speed high-efficiency paddle mixer that maintains a thoroughly mixed grout while waiting to be pumped. The grout pump is connected directly to the agitated storage tank to provide a continuous pumping operation. The grout pump is a 3 stage, size 8, progressing cavity, positive displacement, rotor-stator pump. The rugged steel frame stands up to the toughest conditions on the construction site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance.

Weight Dry:......................................... 2400 lbs / 3600 lbs

Length:................................................ 108" / 126"

Width:.................................................. 60"

Hopper Height:................................... 73"

Mount:................................................ Skid Mounted

Power:................................................ Hydraulic / Electric/Hydraulic / Diesel/Hydraulic

Pump:.................................................

Mixing Tank:.......................................

Hopper Capacity:............................... gal

Max Output:....................................... 35 - 44 GPM

Max Pressure:................................... 261 psi

CG-620 Colloidal Mixer Series

The ChemGrout CG-620 Colloidal Mixer is a skid mounted system. The colloidal mixer is equipped with a high speed centrifugal diffuser-type pump that disperses the cementitous material down to its smallest size to achieve complete particle wetting (or wetness) and a powered bridge breaker to precondition material before entering the colloidal mixing pump. The rugged steel frame stands up to the toughest conditions on the job site. Operator controls are centrally located for efficient production. All components are easily accessible for operating, cleaning and maintenance. The ChemGrout CG-620/630 Colloidal Mixers are designed to be add on units to complement equipment that is already owned by the user.

Weight Dry:......................................... 1050 lbs

Length:................................................ 56" - 69"

Width:.................................................. 42"

Hopper Height:................................... 50"

Mount:................................................ Skid Mounted

Power:................................................

Pump:.................................................

Mixing Tank:.......................................

Hopper Capacity:............................... gal

Max Output:....................................... GPM

Max Pressure:................................... psi

Action Concrete Pumping Supply, LLC

830 E. Southern Avenue • Mesa, Arizona 85204

Phone: (480) 907-7315. Fax: (480) 459-5925